Are you looking to add plastic injection molding to your manufacturing capabilities? Choosing the right machine can be a daunting task, with many factors to consider such as budget, production volume, and part complexity.

But fear not! In this blog post, we will guide you through the process of selecting the perfect plastic injection molding machine for your business needs. So sit back and relax while we help you make an informed decision that will set your business up for success.

Define Your Requirements Versus the Specifications

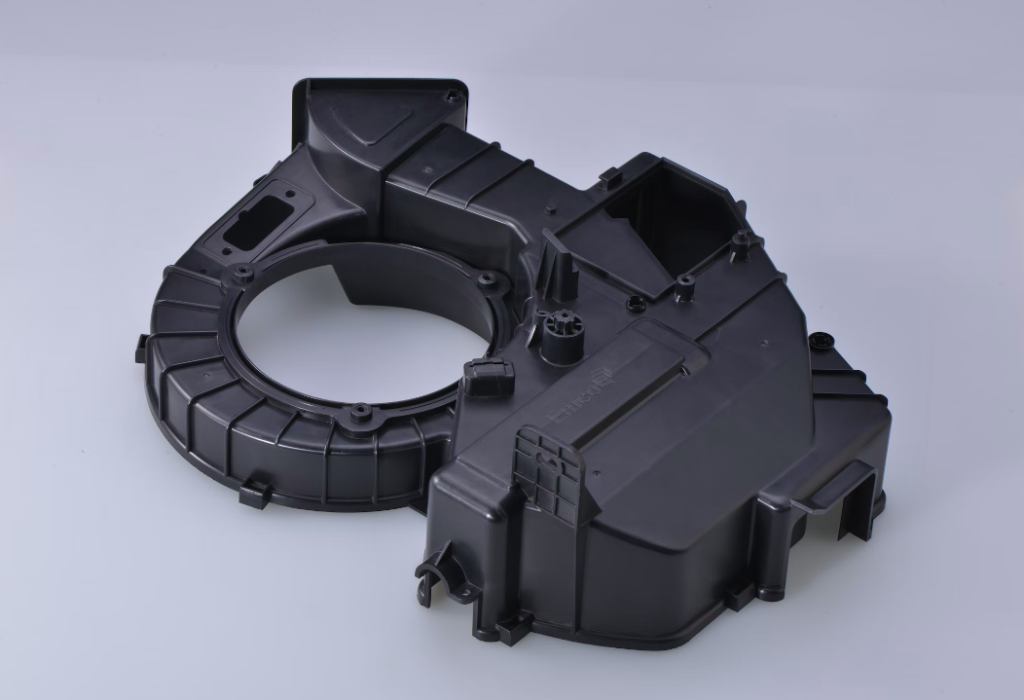

The first step in choosing the right plastic injection molding machine for your business needs is to clearly define your requirements. What are the types of products you want to produce? What are their dimensions?

How much volume do you need to produce? Once you have a clear understanding of your production requirements, you can begin evaluating which machine will best meet those needs.

There are several factors to consider when choosing a plastic injection molding machine, such as:

- Injection pressure

- Clamping force

- Injection volume

- Shot size

- Platen size

- Tie bar distance

- Ejector stroke

Each of these factors will impact the cost, productivity, and quality of your finished product. Work with a reputable dealer or manufacturer to determine which machine is best suited for your specific needs.

Tonnage and Injection

Consider the tonnage and injection pressure required for the parts you plan to produce. Many machines have different levels of injection pressure and varying tonnage ratings, so look for a machine that’s in line with your needs.

Size and Type

Additionally, you should pay attention to the size and type of the machine. Some machines are better suited to certain types of parts than others, so ensure that the machine you choose is capable of producing the products you’re looking for.

Cost of the Machine

Consider the cost of the machine; machines with a higher tonnage may cost more, but they may also last longer and produce better results. Taking all of these factors into consideration will help you find the best machine for your business needs.

Look for Machine Reliability

One of the most important factors is machine reliability. You’ll want to look for a machine that has a good reputation for being reliable and efficient.

Another important factor to consider is the company’s customer service and support. The company should be able to provide you with more information about plastic molding equipment, especially if it’s your first purchase. You’ll want to make sure they’re easy to reach and have a good reputation for helping their customers.

Assess the Machine’s Performance

To ensure that your plastic injection molding machine is performing optimally, it is important to regularly assess its performance. Aside from knowing your specification needs, there are a few key indicators that you can use to gauge the performance of your machine:

Cycle Time

This is the amount of time that it takes for the machine to complete one cycle of operation. The shorter the cycle time, the more efficient the machine is.

Injection Pressure

This is a measure of the amount of pressure that the machine produces during the injection process. The higher the injection pressure, the better the quality of the finished product.

Mold Closing Force

This is a measure of how much force is required to close the mold during the injection process. The higher the mold closing force, the better the quality of the finished product.

If you notice any decrease in performance in any of these areas, it may be indicative of a problem with your machine. By regularly assessing your machine’s performance, you can ensure that it remains in top condition and can produce high-quality products for your business needs.

Check the Machine’s Energy Efficiency

If you’re looking to save money on your plastic injection molding machine, it’s important to choose one that is energy efficient. Check the power rating of the machine. A higher power rating means the machine is more energy efficient.

Check for any energy-saving features that the machine might have. These can include things like automatic shut-off when not in use, and lower power consumption when in standby mode.

Compare the operating costs of different machines. This includes both the initial purchase price and the ongoing running costs like electricity usage. The most energy-efficient machines will often cost more to purchase, but they’ll save you money in the long run.

Look for a machine that has plenty of power, flexibility, and automation options – features that ensure your products will come out high quality and efficient.

The right injection molding machine should allow you to create the products you need on a reliable, cost-effective basis. Contact a manufacturer today to learn more about our selection of injection molding machines.